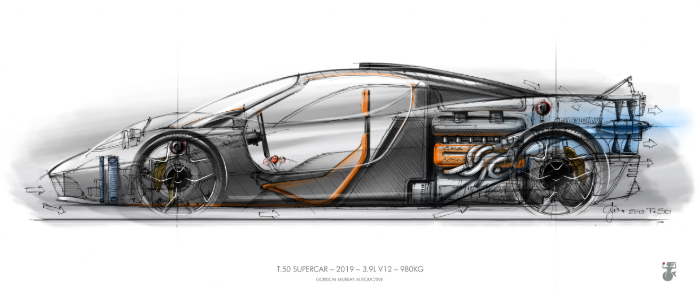

Fabled road and race car designer Gordon Murray’s T.50 supercar is set to be unveiled in early August and, ahead of its launch, details have been unveiled of its Cosworth-developed V12.

Murray has always intended the T.50 to be a natural successor to his seminal work, the McLaren F1. A no-holds-barred, driver-focused machine, which doesn’t put on-paper performance figures ahead of driver engagement. “I have absolutely no interest in chasing records for top speed or acceleration. Our focus is instead on delivering the purest, most rewarding driving experience of any supercar ever built,” said Murray.

With a target weight of 980kg, in a world where most supercars tip the scales at around 1,500kg, a lightweight powertrain was inevitable. Why a V12, rather than a downsized, boosted I4? As Murray said, “More than half of any truly great driving experience is delivered by the engine, so right from the start I set the highest possible benchmark – to create the world’s greatest naturally aspirated V12.

“To be truly remarkable, an engine needs to have the right character; highly-responsive, an amazing sound, engaging torque delivery, free-revving, and it has to be naturally aspirated. For all those reasons, the engine in the T.50 was never going to be anything other than a V12.”

Murray has chosen a partner with whom he had a longstanding relationship, Cosworth, to develop the engine. According to the designer, his brief was clear – the engine had to be light. It had to have the fastest response time of any engine ever built for the road, aping the target set for the McLaren F1. It also had to be high revving, specifically it needed to be able to achieve a redline of at least 11,500rpm, matching the benchmark Murray set with his Light Car Company Rocket. It comfortably beats this standard, achieving 12,100rpm. Finally, it had to be characterful, sound superb, and look good.

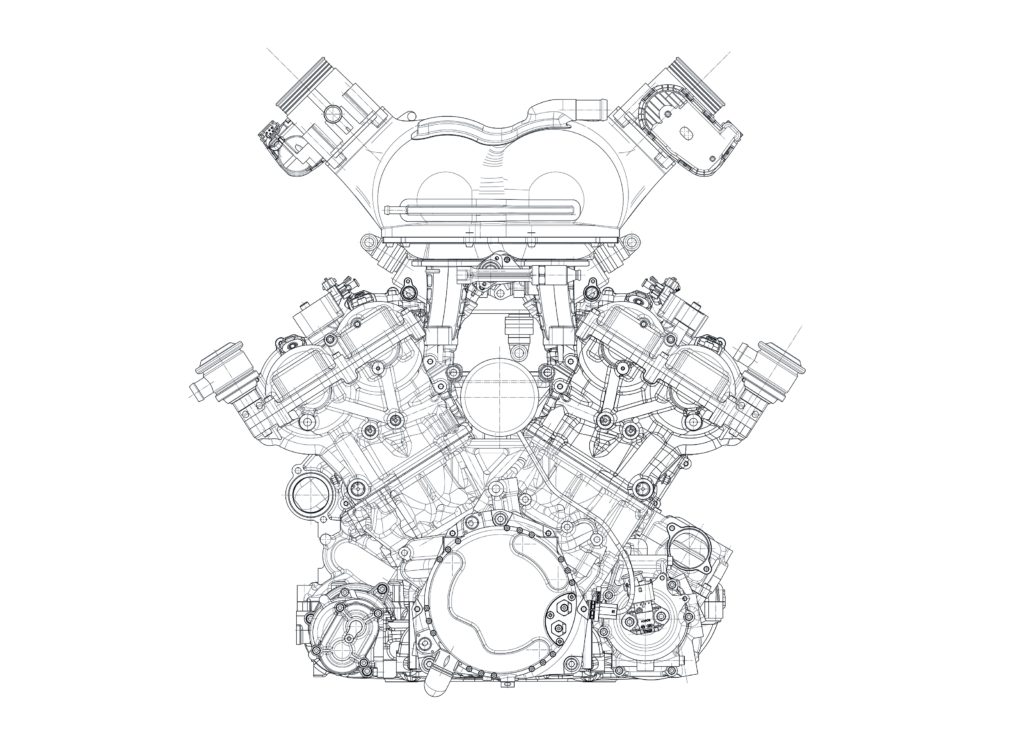

To meet this brief, Cosworth devised a 3.9-liter, naturally aspirated unit, similar in some ways to the 6.5-liter V12 developed for the Aston Martin Valkyrie project, but in a much lighter, and higher revving package. Additionally, with no hybrid system to provide torque infill at low RPM, a particular focus was placed on driveability. Impressively, the company says that 71% of the engine’s maximum 467Nm of torque is available from 2,500 rpm.

The engine architecture is undeniably more race than road car inspired. The 65° V12 is used as a semi-stressed chassis member and utilizes a gear driven valvetrain. Of course, the engine features dry sump lubrication and all of the internals required to survive high RPM operation such as titanium connecting rods and valves as well as a highly optimized forged steel crank weighing just 13kg. Maximum power is claimed at 663bhp, netting an impressive specific output of 166bhp/liter, and remarkably the compact unit weights just 178 kg.

The engine architecture is undeniably more race than road car inspired. The 65° V12 is used as a semi-stressed chassis member and utilizes a gear driven valvetrain. Of course, the engine features dry sump lubrication and all of the internals required to survive high RPM operation such as titanium connecting rods and valves as well as a highly optimized forged steel crank weighing just 13kg. Maximum power is claimed at 663bhp, netting an impressive specific output of 166bhp/liter, and remarkably the compact unit weights just 178 kg.

The architecture of the engine was almost as important to Murray as its performance: it had to be compact and, from a chassis dynamics perspective, he wanted to better the McLaren F1’s already low crank center height of 125mm. This it does with ease, with the crank center just 85mm from the lowest extent of the engine’s structure.

Aesthetics also had a role to play, the designer wanted the engine to echo the appearance of V12s of old; when viewed from the top, it had to be clean and uncluttered. As such, Cosworth has gone to great lengths to place ancillaries either internal to the block or tucked away out of sight. All that can be seen from above are the inlet trumpets and exhaust manifolds.

Coupled to the engine is an Xtrac-developed, 6-speed, H-pattern transmission. It is an entirely bespoke creation and again, lightweighting is key. For example, in what may be a road car first, it utilizes a thin wall cast aluminum casing, and expensive and complex manufacturing process favored in high end racing transmissions.

In the context of a modern supercar, an H-pattern box may seem archaic, but again, the focus is on driver engagement rather than outright performance. “Maximizing the driver’s connection with the T.50 was central to our decision-making. So, matching the V12 engine to an exquisite short-shifting manual gearbox was an easy decision to make,” remarked Murray.

In many ways, when the T.50 is officially launched on August 4, it will be a requiem to the V12 engine. With ever-pressing emissions targets, even manufacturers such as Ferrari are struggling to justify their use, but for Murray, it’s clear there could be no substitute for the ultimate driver’s engine.

Cosworth GMA V12 specification

Engine

Type number Cosworth GMA

Configuration V12 semi-structural

V-angle 65°

Capacity 3,994cc

Bore 81.5mm

Stroke 63.8mm

Compression ratio 14:1

Max power 663ps @ 11,500rpm

Power to weight ratio 672ps per metric ton

Weight to power ratio 150kg per 100ps

Max torque 467Nm @ 9,00 rpm

Flexibility 71% of max torque @ 2,500rpm

Maximum rpm 12,100rpm

Valvetrain Gear driven double overhead camshafts

Inclined axis 4 valves per cylinder – variable valve timing on inlet / exhaust

Induction system RAM induction airbox – four throttle bodies – Direct Path Induction Sound

Exhaust system Inconel and Titanium

Lubrication system Dry sump

Cooling system Water-cooled – twin aluminum front radiators

Oil cooling system Single aluminum rear radiator

Ignition system 12 individual coils 12V

Starter/alternator 48V gear driven integrated starter/generator

Exhaust emission control Four catalytic convertors with Lambda sensors and secondary air injection

Engine block Aluminum alloy

Cylinder heads Aluminum alloy

Connection rods Titanium

Valves Titanium

Total engine weight 178kg

Engine mounting Semi-structural-inclined axis shear mounting (IASM)

Power density 166ps/liter

Transmission

Configuration Transverse with high-speed bevel gears and spur gear final drive

Speeds 6 speeds + reverse: full synchro mesh

Gear change Manual H-pattern with reverse lock-out

Differential Limited slip (Salisbury)

Clutch 184mm diameter – Triple plate carbon silicone and titanium

Drive line Tripod joints and gun drilled driveshafts

Casing Aluminum alloy

Lubrication Pumped lubrication

Oil cooling Single aluminum alloy radiator

Ratios

First 2.833:1

Second 2.095:1

Third 1.577:1

Fourth 1.226:1

Fifth 0.971:1

Sixth 0.744:1

Input bevel 1.688:1

Final drive 3.176:1

Optional overdrive (6th) 0.595:1

Weight 80.5kg