Researchers at the US Oak Ridge National Laboratory say they have additively manufactured parts using a lightweight aluminum alloy and demonstrated its ability to resist creep or deformation at 300°C. The material’s properties will be demonstrated using additive manufactured pistons in a four-cylinder, turbocharged engine.

The researchers noted that while AM production of aluminum alloys is now well established, materials tend to be near-eutectic Al-Si alloys, which while useful do not possess the material properties of conventional wrought alloys.

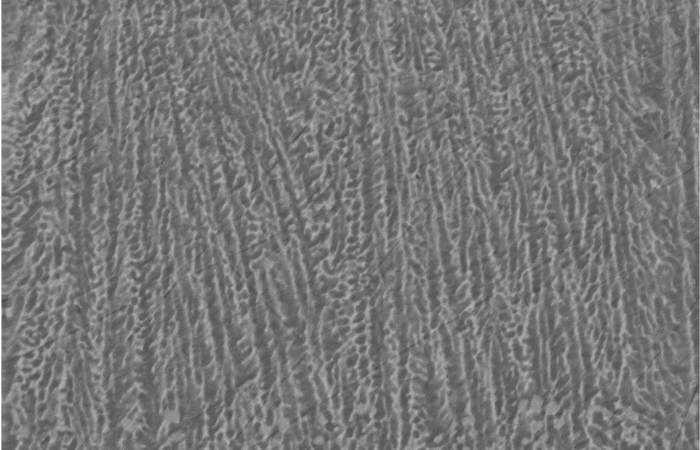

The alloy, which combines aluminum with cerium and other metals, was printed using a laser powder bed system that deposits one thin layer of material at a time for precise results.

“Using powder-bed 3D printing allowed the alloy to rapidly solidify into fine, stable strengthening particles in the microstructure, resulting in the remarkable high-temp creep resistance we measured,” ORNL researcher Ryan Dehoff said. “We expected notable improvements, but were surprised by how strong and stable these alloys proved to be.”